In India’s semi-urban and industrial zones, especially in Bihar and Jharkhand, there’s rising demand for durable and cost-efficient factory and warehouse sheds. Small business owners, farmers, and industrial operators are looking for structures that are quick to build, lightweight, and long-lasting, without breaking the bank.

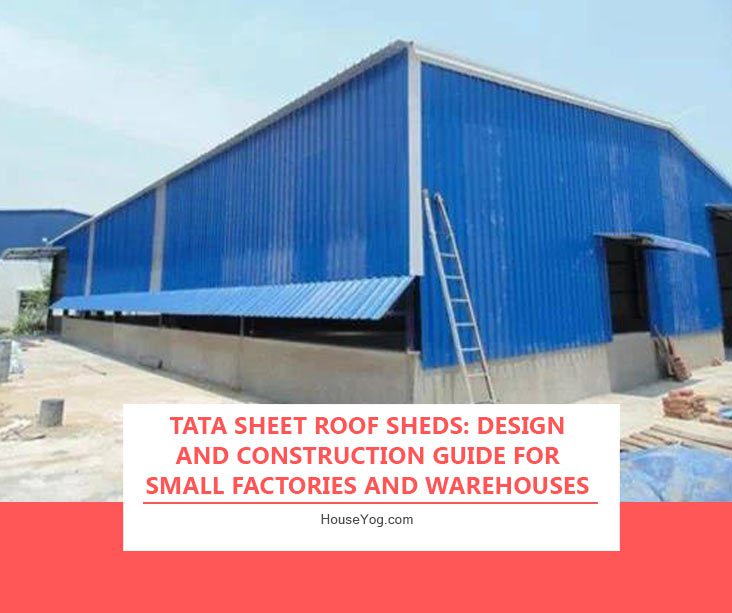

That’s exactly where Tata sheet roofing shines. Known for its strength, weather resistance, and long life, Tata roofing sheets are widely used in warehouses, workshops, godowns, and small factories. And when paired with a proper foundation and steel frame layout, they offer a highly functional and scalable solution.

What is a Tata Sheet Roof Shed?

A Tata sheet roof shed is a steel-frame building structure covered with Tata-brand roofing sheets, typically made of galvanized iron (GI) or color-coated steel. These sheds are used for a wide range of industrial and agricultural purposes.

Unlike traditional RCC buildings, these sheds:

- Are much faster to build (in weeks, not months)

- Can span large widths without central columns

- Are easier to modify or expand later

- Require less maintenance

They’re ideal for small and medium-sized industries looking to optimize both construction time and cost.

Key Elements of Tata Sheet Shed Design

Designing a durable and efficient shed is more than just assembling steel and sheets. It requires careful planning of foundations, load-bearing members, roofing details, and environmental considerations. Below are the four key components to plan for:

1. Foundation & Column Footing

Every great structure starts with a strong foundation. Whether you’re building on soil, sand, or semi-rocky terrain, your foundation must be engineered to bear the load of the steel frame and the roof.

Key Design Considerations:

- Use RCC footings with anchor bolts

- Ensure footing depth is based on soil type

- Design plinth beams or flooring based on your machinery or storage load

- Plan for drainage and rainwater runoff around the base

2. Steel Frame Structure

This is the skeleton of your shed. The steel frame must be strong, lightweight, and dimensionally accurate to support roofing sheets and external loads like wind or rain.

Design Considerations:

- Use ISMB/ISMC or tubular steel for columns and rafters

- Add bracing and tie members for rigidity

- Plan for clear span if you need unobstructed space inside

- Decide the height (typically 14-22 ft at center) based on your function

- Include purlins and supports at regular spacing for sheet fixing

3. Roofing Layout with Tata Sheets

The roof is not just about covering the structure, it protects your goods, controls temperature, and enhances durability. Tata sheets, like Tata Shaktee or Tata Durashine, are ideal for India’s climate because they are rust-resistant, UV-protected, and available in multiple colors and profiles.

Design Guidelines:

- Maintain a roof slope of 8° to 15° for proper rainwater drainage

- Use Tata GI or color-coated sheets with 0.4 mm to 0.6 mm thickness

- Install ridge vents, louvers, or translucent sheets for natural lighting and ventilation

- Ensure proper overlap and use anti-rust screws with washers

- Don’t forget flashing and gutter lines for drainage

4. Ventilation, Lighting & Openings

Comfort, safety, and functionality depend on air and light. These factors reduce heat buildup, avoid dampness, and make the shed usable for long hours.

Must-Haves:

- Turbo ventilators or ridge ventilators for passive airflow

- Louvers or jali mesh on side walls

- Skylight strips or polycarbonate sheet panels for natural lighting

- Rolling shutters or industrial gates depending on your entry needs

- Electrical and plumbing provisions if needed

Benefits of Using Tata Sheet Roof for Factory or Warehouse

Choosing Tata sheets offers not just brand trust, but also a list of practical benefits — especially for small-scale industrial or commercial use:

- Long Life: GI and coated sheets last 15–25 years

- Quick Build: Entire shed can be constructed within 3–5 weeks

- Customizable: Designs can be tailored for different sizes, uses, or future expansion

- Low Structural Load: Lighter than RCC, saving cost on foundation

- Corrosion Resistance: Tata sheets are coated and weather-tested

- Low Maintenance: Requires minimal painting or treatment

Tata Sheet Shed Design Considerations

Before finalizing your shed design, it’s important to analyze how the space will be used — now and in the future. A good layout should allow for scalability and hassle-free operation.

Points to Plan:

- Your plot size and layout direction

- Clear width, length, and roof height needed

- Nature of business i. e. storage, production, assembly

- Ventilation and access points

- Service areas, parking, and utilities

- Drainage and water harvesting, especially for larger plots

Professional architectural support ensures all these elements are optimized and compliant.

Tata Sheet Shed vs RCC Roofing: A Quick Comparison

| Feature | Tata Sheet Shed | RCC Roofing |

| Construction Time | 2–4 weeks | 2–3 months |

| Structural Load | Light | Heavy |

| Flexibility | Easily expandable | Rigid |

| Cost (Per Sq Ft) | Lower | Higher |

| Maintenance | Minimal | Moderate |

For most industrial uses in small towns, Tata sheet sheds are the smarter choice.

Conclusion: Build Efficiently with the Right Design

If you’re planning to set up a factory shed, cold storage, godown, or any industrial unit, Tata sheet roofing offers the right balance of performance, affordability, and speed. But to get the full value, the shed needs to be properly designed, from the ground up.

At Houseyog, we’ve worked with clients across Bihar, Jharkhand, Odisha and West Bengal to design customized shed layouts for small warehouses, godowns, rice mills, and industrial workshops. Each design is tailored to plot size, location, and utility, and includes complete floor plans, elevations, structural and roofing drawings.

Need Help Planning Your Shed?

Talk to our expert architects today for:

- Custom floor plan & shed layout

- Structural steel design

- Foundation drawings

- 3D elevations

- Approval-ready documents

Call or WhatsApp: +91 75960 58808 now!!

Frequently Asked Questions (FAQ)

Tata roofing sheets typically last 15 to 25 years, depending on the material, coating, and local weather conditions. Proper installation and periodic checks ensure long-term durability with minimal maintenance.

Yes, Tata sheets are designed to withstand heat, rain, and wind, making them ideal for most Indian climates, including high-moisture zones like Bihar and Jharkhand. They’re rust-resistant, UV-protected, and can handle monsoon loads if installed with proper slope and drainage.

An ideal slope for Tata sheet roofing is between 8° and 15°, depending on the shed size and local rainfall. This ensures proper water drainage and reduces the risk of water accumulation or leakage.

The cost varies based on shed size, structural design, and location. On average, expect to spend ₹500-₹900 per sq ft, including foundation, steel framing, and roofing. For a customized cost estimate, contact our team at +917596058808.

Yes! One of the biggest advantages of Tata sheet sheds is ease of expansion. You can extend the structure by adding bays or covering open areas without disturbing the existing framework, a great advantage for growing businesses.

Yes, most towns and cities require basic approval or notice for industrial or commercial sheds. At Houseyog, we provide approval-ready drawings and can guide you through the process.