From plot to insulation, everything you need to know before building a cold storage warehouse in India.

As agriculture expands in small towns and rural belts across Bihar, Jharkhand, Odisha, and Uttar Pradesh, the demand for cold storage facilities is at an all-time high. Whether you’re a farmer, a trader, or a new agri-entrepreneur, building a cold storage setup can help reduce post-harvest losses, increase profit margins, and improve local food supply.

But designing a cold storage facility isn’t the same as building a regular warehouse. It requires:

- Strategic layout planning

- Thermal insulation

- Efficient ventilation and energy usage

- And compliance with industry safety and hygiene norms

In this post, we’ll walk you through everything, from selecting the right plot to planning the building, insulation, cooling, and loading areas.

Let’s dive in.

1. Choose the Right Plot for Cold Storage Construction

Before you lay a single brick, the success of your cold storage facility hinges on where and how you build it.

Location matters, not just for convenience, but for long-term efficiency and logistics. A poor site can lead to drainage issues, delivery delays, and increased energy costs. Whether you’re setting up in Darbhanga, Hazaribagh, or Balasore, evaluating your plot correctly is the first step toward a profitable project.

Before designing your building, consider the following factors:

- Plot Size: Minimum 5000–8000 sq ft for small capacity (50-100 MT), larger for multi-chamber units

- Road Access: Must accommodate trucks and tractors; 20 ft wide road recommended

- Drainage & Water: Plot should be above road level with access to borewell or water source

- Electricity: Nearby power line access is critical for cold rooms and compressors

If you’re unsure whether your site is suitable, our site planning services can help assess it for you free of cost.

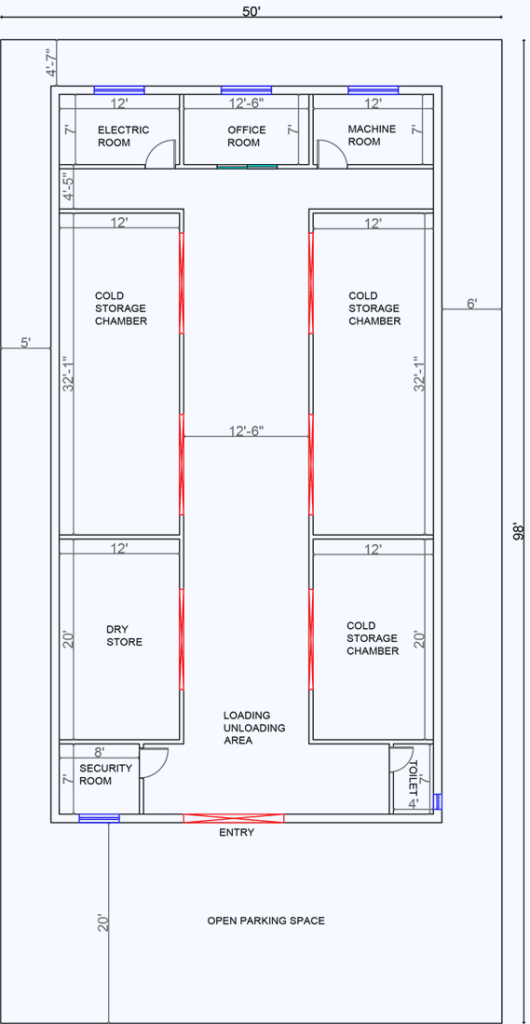

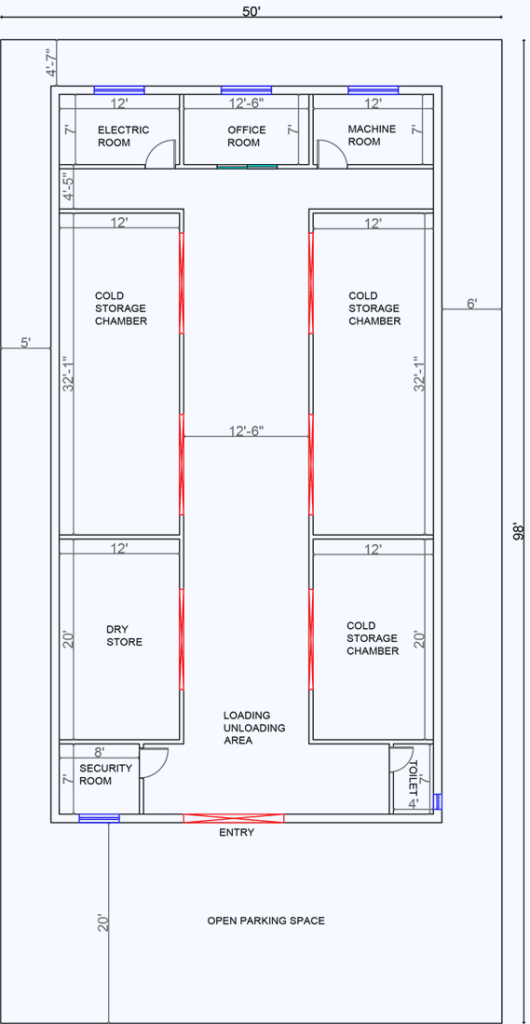

2. Layout Planning: Zones in a Cold Storage Facility

Designing a cold storage unit is about more than just chilling rooms, it’s about smart zoning.

Each part of your facility, from unloading dock to office cabin, must be thoughtfully placed to maximize cooling efficiency, reduce material movement, and ensure hygiene. A well-zoned facility saves energy, avoids cross-contamination, and scales better as demand grows.

Here are the essential zones to plan:

| Zone | Description |

| Receiving/Unloading Area | Covered dock with slope; near main gate |

| Pre-Cooling/Sorting | Optional but ideal for perishable crops like fruits/veggies |

| Cold Chambers | 1 or more rooms (10–100 MT each); fully insulated |

| Compressor & Machine Room | For ammonia or freon-based cooling units |

| Admin/Office Block | Small area for management/staff |

| Toilet + Staff Room | Especially if night shift/seasonal use expected |

The ideal shape is rectangular, with chambers centrally placed and services on the sides.

3. Temperature Zones: What Are You Storing?

Not all cold storages are the same, and what you store determines everything from temperature control to wall thickness.

Whether you plan to store onions, apples, paneer, or frozen meat, each commodity demands a different level of cooling, stacking method, and chamber design. Clarifying your use-case helps determine insulation, refrigeration units, and space allocation.

Your chamber design will depend on what you’re planning to store.

| Commodity | Ideal Temp | Storage Tip |

| Fruits | 0–4°C | Use stacking crates |

| Vegetables | 4–10°C | Pre-cool before entry |

| Grains/Pulses | 10–15°C | Dry storage is enough in some cases |

| Dairy/Meat | -5 to -18°C | Requires deep freezer units |

Chamber design, insulation thickness, and cooling capacity will vary based on this.

4. Structural & Civil Planning for Cold Storage

A strong foundation and insulated envelope are essential for temperature integrity and durability.

Cold storage buildings need civil and structural designs that support heavy equipment, prevent moisture seepage, and allow retrofitting for future chambers. Reinforced RCC flooring, vapor barriers, and insulated sandwich panels must all work in harmony.

- RCC plinth 3-4 ft above ground

- Use insulated sandwich PUF panels for walls and roof (60–120 mm)

- Doors must be insulated with gasket lock

- Flooring: anti-skid cement concrete + vapor barrier underlay

We offer full foundation + structure design consulting for cold storage buildings.

5. Ventilation, Drainage & Safety Considerations

Ignoring support systems like drainage or ventilation can lead to costly downtime or spoilage.

Good design goes beyond insulation, it includes how water drains, how fresh air circulates in buffer areas, and how fire risks are minimized. These details often get overlooked but are crucial for operational safety and compliance.

- Drainage slope inside chambers for water release

- Natural or forced ventilation for non-cooled zones

- Fire safety norms – use fire-rated panels, exit signage

- Insulated roof or false ceiling to reduce heat load

6. Legal & Govt Norms to Keep in Mind

Getting government approvals and subsidies requires smart paperwork and the right drawings.

Cold storages fall under semi-commercial infrastructure, often regulated by agriculture or industries departments. Following building codes, pollution control norms, and subsidy requirements can help reduce costs and avoid future legal trouble.

- Register your project with local agriculture or industry department

- Get pollution clearance if ammonia-based system is used

- Subsidies under schemes like MIDH (Mission on Integrated Development of Horticulture) may apply

- Building plans must comply with local municipal/town norms

We can guide you through design approvals and sanction-ready layouts.

7. Cold Storage Construction Cost (Small Town Estimate)

One of the biggest concerns for investors is: how much will this cost me?

While prices vary by region and technology used, getting a ballpark estimate for construction, equipment, and insulation helps you budget better and apply for loans or grants more confidently. Approximate cost breakdown for 50–100 MT cold storage (excluding land):

| Component | Cost (approx.) |

| RCC Foundation + Flooring | ₹500–700/sq ft |

| PUF Panel Walls & Roof | ₹900–1100/sq ft |

| Cooling Equipment | ₹12–20 lakh |

| Electrical + Ducting | ₹2–4 lakh |

| Total Project | ₹30–50 lakh (small scale) |

Request a custom quote based on your capacity & cooling type.

8. Should You Go for Prefab or RCC Construction?

Both RCC and pre-engineered (PEB) methods have pros and cons — and the choice depends on your goal.

While RCC is durable and time-tested, PEB allows faster setup and expansion. Understanding your budget, location, and urgency will help you decide between the two construction styles for your cold storage facility.

| Criteria | RCC | PEB/Prefab |

| Durability | ✅✅✅ | ✅✅ |

| Insulation | External panels | Integrated |

| Speed | 3–4 months | 1–2 months |

| Cost | Medium | Slightly higher per sq ft |

| Best For | Long-term, high load | Remote/flexible setups |

We can help you plan for either based on budget and plot conditions.

Sample Layout Plan (Optional Visual Section)

Consider embedding a sample layout showing:

- Gate → Dock → Chamber → Compressor → Staff Room

Let me know if you’d like a sample floor plan image designed for this post.

Conclusion: Plan Smart, Build Right

Building a cold storage facility in a small town or rural area can be a game-changer for farmers, traders, and food businesses. But without proper planning, insulation, zoning, and equipment layout, you may lose more than you gain.

Whether it’s a small 50 MT chamber or a large 300 MT setup, the layout, construction, and cooling systems must work together. And, if you need help planning your cold storage shed or warehouse, talk to our experts today. Call or WhatsApp: +91 75960 58808

Or explore our industrial design services

FAQ: Cold Storage Construction in India

Around 5000 sq ft for a basic 50 MT chamber with loading dock and utility space.

PUF (polyurethane foam) sandwich panels are most common, 60 – 120 mm thick.

RCC builds: 3-4 months. PEB prefab: 1-2 months (excluding licensing).

Yes, schemes under NHM or state-level agriculture subsidies are available, but pre-approval is needed.

IMAGE: WE ARE WORKING ON IT